Sustainable Waste-to-Bioproducts Engineering

SWBEC is focused on generating technologies that promote sustainability, environmental protection, and the generation of bioproducts through research from the laboratory to pilot scale.

These technologies are further translated through refereed publication and a network of industry partners.

Center Projects

The Sustainable Waste-to-Bioproduct Engineering Center is currently working on the IPP (Industry Partnership Program) project titled "Bioenergy & Waste Reduction from Municipal Reclaimed Water." The project is a collaboration with the Central Valley Water Reclamation Facility (CVWRF), WesTech-inc., and the Sustainable Waste-to-Bioproducts Engineering Center (SWBEC) at Utah State University. Dr. Ron Sims is the principal investigator on the project.

Wastewater Sources

SWBEC is able to use a variety of sources of wastewater. Essentially any industry from meat packing plants, textile industries, and cheese industries can transform their waste into useful bioproducts. Our research has been primarily focused on the waste sources of our collaborators shown below.

Hydraulic Fracturing Waste

Swine Waste

Dairy Waste

Municipal Wastewater

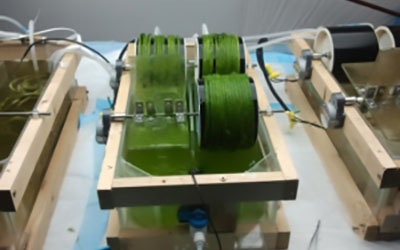

Growing Algae Biofilms

Algal biofilm systems used to harvest algae, and has been shown to be an easier and more cost effective to method to harvest biomass than suspended algal growth systems. SWBEC’s projects aim to optimize biofilm growth and the rate of nitrogen and phosphorous removal. In addition, SWBEC characterizes the biofilm population to design the best possible biofilm systems.

Harvesting Algae

The techniques currently employed in microalgae harvesting and recovery include centrifugation, flocculation, filtration and screening, gravity sedimentation, flotation, and electrophoresis techniques. Of all the harvesting methods, precipitation of microalgae is shown to be the most efficient method for harvesting biomass on a large scale.

Our research focuses on synthesizing cationic starch, which serves as an organic coagulant/flocculant for harvesting algal biomass. Starch is abundant in wastewater, inexpensive and biodegradable. Starch can be modified to exhibit positive charges. The cationic starch thus formed acts as a polyelectrolyte, which helps in precipitating algae by subsequent coagulation (charge neutralization) and flocculation (bridging) owing to the inherent polymer structure of starch.

Extracting Oil from Algae

The production of biodiesel from algal biomass requires the extraction of the lipids or oil from the harvested algae biomass. However, typical methods of extracting oil from algae have several drawbacks:

- Algal biomass must be dried prior to traditional solvent extraction processes

- Solvent extraction of algal biomass requires large volumes of solvent which can be costly

- Contamination of the algal oil extract with pigments such as chlorophyll requires further purification

Our wet lipid extraction was developed to help address issues associated with algal lipid extraction and biodiesel production.

Producing Bioproducts

The wet lipid extraction process produces several streams, each of which can be used to produce different bioproducts. Algae biomass has a high sugar content, which is attractive for producing biofuels. Another stream is optimal for bacterial growth which can produce PHB, a bioplastic. This stream can also be used to produce a phycocyanin, a therapeutic that has anti-inflammatory, anti-viral, and antioxidant properties. Recently, options of creating animal feed using algae bioproducts have been explored.

Industry Partners, Collaborators, and Contributors